Motor Damage Detection with AI

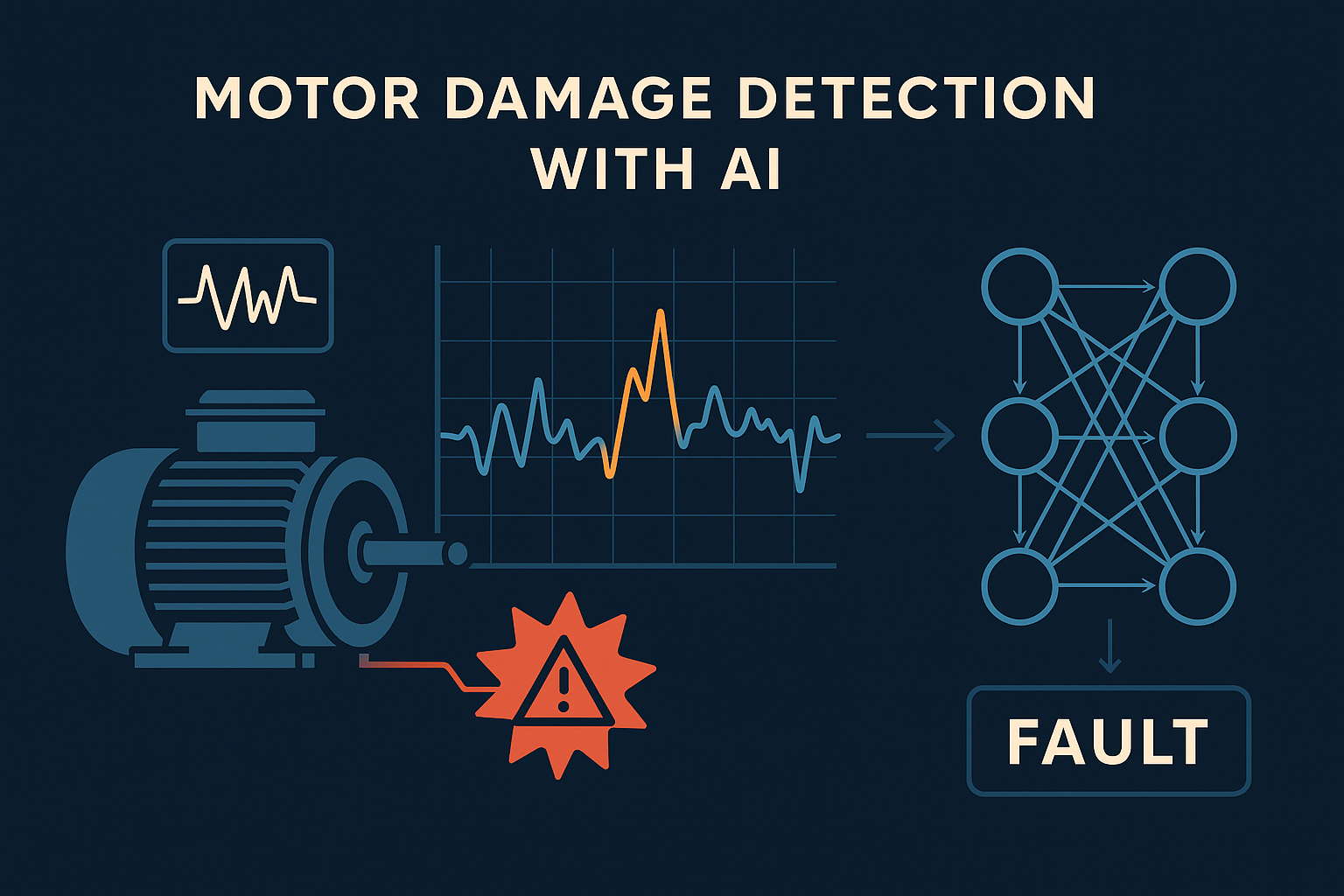

This project focuses on developing a robust AI-powered system for detecting and classifying damage in industrial electric motors before catastrophic failure occurs. By combining principles of data analysis, signal processing, and machine learning, the system aims to reduce maintenance costs, prevent unplanned downtime, and extend motor lifespan.

The Goal

The core goal is predictive maintenance: automatically identifying early signs of wear, imbalance, or failure in motors using historical and real-time sensor data — allowing timely intervention before a breakdown happens.

System Overview

The project consists of three main stages:

1. Data Acquisition & Preprocessing

Sensor data from vibration, current, and acoustic signals are used. Preprocessing techniques like Fast Fourier Transform (FFT), windowing, and signal normalization are applied to extract meaningful patterns from raw data.

2. Feature Engineering

Time-domain and frequency-domain features such as RMS, kurtosis, spectral entropy, and harmonics are extracted. Dimensionality reduction is applied where necessary.

3. Machine Learning Models

Multiple algorithms were evaluated, including Random Forest, SVM, Gradient Boosting, and LSTMs for temporal analysis. Model performance is cross-validated using labeled motor health states: Healthy, Minor Fault, and Severe Fault.

Key Technologies

- Python: Pandas, Scikit-learn, NumPy, SciPy

- Visualization: Matplotlib & Seaborn

- Environment: Jupyter Notebooks

This private project reflects a practical application of AI in industrial reliability engineering, developed as part of an applied research effort.